Fresh air supply + High Efficiency Purification+ Energy recuperative ( reducing running cost of cooling or heating air conditioning system) Energy recovery ventilation (ERV) is the energy recovery process of exchanging the energy contained in normally exhausted building or space air and using it to treat (precondition) the incoming outdoor ventilation air in residential and commercial HVAC systems. During the warmer seasons, the system pre-cools and dehumidifies while humidifying and pre-heating in the cooler seasons. The benefit of using energy recovery is the ability to meet the ASHRAE ventilation & energy standards, while improving indoor air quality and reducing total HVAC equipment capacity. | |

| Higher Energy Efficiency and Ecology by Powerful Motors HOLTOP XHBQ-D*DCPMTHC Series Commercial energy recovery ventilators is built with higher efficiency BLDC motors, power consumption is reduced by up to 70%, resulting in significant energy saving. Advanced Intelligent control is suitable for most of the projects’ air volume and ESP requirements. |

| |

| Higher efficiency with Holtop 3rd generation enthalpy exchanger (Total heat Recuperator)Holtop crossflow enthalpy exchanger, heat recovery efficiency up to 82% in winter, the allowance of moisture exchange between fresh air and exhaust air make a soft indoor temperature and humidity.The 3rd generation enthalpy exchanger is made of the latest nanofiber structure to ensure higher efficiency. The heat exchange materials are mildew resistance and fire retardant. |

Good thermal insulation The whole series is integrated with EPS structure, effectively preventing condensation, and improving thermal insulation and saving energy consumption.

Good thermal insulation The whole series is integrated with EPS structure, effectively preventing condensation, and improving thermal insulation and saving energy consumption. New Primary Filter

New primary filter is made of aluminium alloy frame and rubber filtration materials with nice appearance and longer service life.

Sub-HEPA F9 Filter Integrated Optional

Optional sub HEPA F9 filter, particle diameter under 2.5μm can be filtered effectively, IAQ (indoor air quality) will be increased obviously

. |

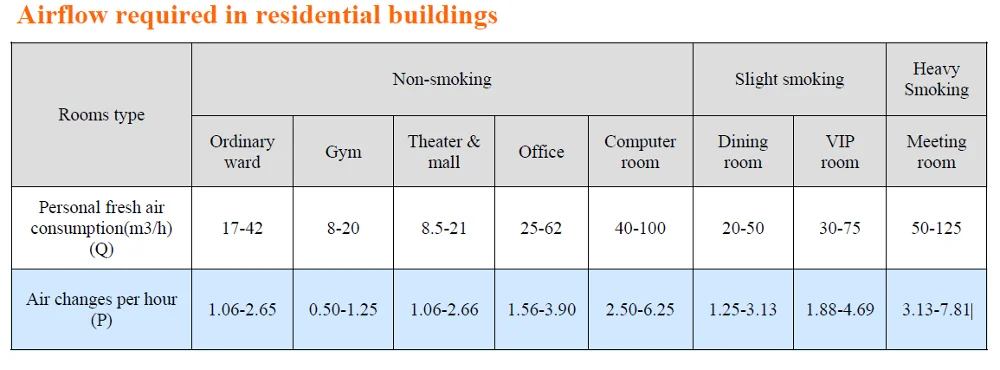

Example The area of a computer room is 60 sq. meters (S=60), the net height is 3 meters (H=3), and there are 10 per-sons (N=10) in it. If it is calculated according to “Personal fresh air consumption”, and assume that: Q=70, the result is Q1 =N*Q=10*70=700(m3/h) If it is calculated according to “Air changes per hour”, and assume that: P=5, the result is Q2 =P*S*H=5*60*3=900(m3) Since Q2 > Q1 , Q2 is better for selecting the unit. As to special industry such as hospitals (surgery and the special nursing rooms), labs, workshops, airflow re-quired should be determined in conformity with regulations concerned.

Example The area of a computer room is 60 sq. meters (S=60), the net height is 3 meters (H=3), and there are 10 per-sons (N=10) in it. If it is calculated according to “Personal fresh air consumption”, and assume that: Q=70, the result is Q1 =N*Q=10*70=700(m3/h) If it is calculated according to “Air changes per hour”, and assume that: P=5, the result is Q2 =P*S*H=5*60*3=900(m3) Since Q2 > Q1 , Q2 is better for selecting the unit. As to special industry such as hospitals (surgery and the special nursing rooms), labs, workshops, airflow re-quired should be determined in conformity with regulations concerned.